Self-Assembling Nanorods: Berkeley Lab Researchers Obtain 1, 2 and 3D Nanorod Arrays and Networks

A relatively fast, easy and inexpensive technique for inducing nanorods – rod-shaped semiconductor nanocrystals – to self-assemble into one-, two- and even three-dimensional macroscopic structures has been developed by a team of researchers with the U.S. Department of Energy (DOE)’s Lawrence Berkeley National Laboratory (Berkeley Lab). This technique should enable more effective use of nanorods in solar cells, magnetic storage devices and sensors. It should also help boost the electrical and mechanical properties of nanorod-polymer composites.

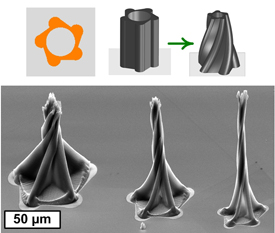

Leading this project was Ting Xu, a polymer scientist who holds joint appointments with Berkeley Lab’s Materials Sciences Division and the University of California (UC) Berkeley’s Departments of Materials Sciences and Engineering, and Chemistry. Xu and her research group used block copolymers – long sequences or “blocks” of one type of monomer bound to blocks of another type of monomer – as a platform to guide the self-assembly of nanorods into complex structures and hierarchical patterns. Block copolymers have an innate ability to self-assemble into well-defined arrays of nano-sized structures over macroscopic distances. (more…)