A new study from researchers at North Carolina State University sheds light on how a technique that is commonly used for making single-metal nanoparticles can be extended to create nanoparticles consisting of two metals – and that have tunable properties. The study also provides insight into the optical properties of some of these nanoparticles.

Tuning the optical properties of nanoparticles is of interest for applications such as security technology, and for use in making chemical reactions more efficient – which has multiple industrial and environmental applications.

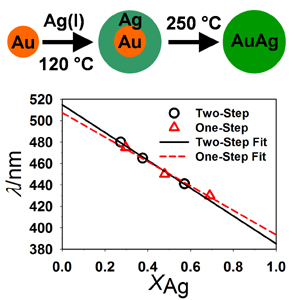

The researchers created core/shell nanoparticles with a gold core and silver shell, as well as alloy nanoparticles, which mix the gold and silver. The researchers also characterized the optical properties of these nanoparticles. “Silver and gold have unique optical properties arising from their specific interactions with the electric field of light,” says Dr. Joe Tracy, an assistant professor of materials science and engineering at NC State and co-author of a paper describing the study. “By manipulating the ratio of the metals, and whether the nanoparticles have core/shell or alloy structures, we can alter their optical properties with control.”

This diagram shows how researchers created the core/shell nanoparticles, and alloy nanoparticles, from gold and silver. Image credit: North Carolina State University

The researchers synthesized the nanoparticles using a technique called “digestive ripening.” The technique has been used to create single-metal particles for approximately a decade, but there have been limited studies of core/shell and alloy nanoparticles created using digestive ripening. However, the comprehensive nature of this study may make it more common.

“This study, along with related work by others, shows that digestive ripening is a viable method for creating multi-component metal nanoparticles. We used gold and silver, but the same principles would likely apply to other metals,” Tracy says. “Our detailed evaluation of this synthetic approach should help other researchers explore other kinds of binary metal nanoparticles.”

Digestive ripening relies on the use of ligands, which are small organic molecules with parts that bond directly to metals. The ligands are usually anchored to the metal cores of the nanoparticles and prevent the nanoparticles from clumping together, which allows them to be suspended in solution. Digestive ripening occurs when the ligands are able to transport metal atoms from the core of one nanoparticle to another – resulting in a more homogenous size distribution among the nanoparticles.

The researchers used digestive ripening to create a solution of gold nanoparticles of similar size. When they introduced silver acetate into the solution, the ligands transported silver atoms to the surfaces of the gold nanoparticles, resulting in nanoparticles with gold cores and silver shells.

Researchers then transferred the nanoparticles into a second solution, containing a different ligand. Heating this second solution to 250 degrees Celsius caused the metals to diffuse into each other – creating nanoparticles made of a gold-silver alloy.

The researchers also created gold-silver alloy nanoparticles by skipping the shell-creation step, introducing silver acetate into the second solution, and raising the temperature to 250 degrees Celsius. This “shortcut” method has the benefit of simplifying control over the gold-to-silver ratio of the alloy.

The paper, “Synthesis of Au(core)/Ag(shell) Nanoparticles and their Conversion to AuAg Alloy Nanoparticles,” was published online Dec. 13 by the journal Small. The research was funded by the National Science Foundation and NC State. The lead author of the paper is Matthew Shore, who was an undergraduate at NC State when the research was done. Co-authors include Tracy, NC State Ph.D. student Aaron Johnston-Peck, former NC State postdoc Dr. Junwei Wang, and University of North Carolina at Chapel Hill assistant professor Dr. Amy Oldenburg.

NC State’s Department of Materials Science and Engineering is part of the university’s College of Engineering.

*Source: North Carolina State University