How a ‘motor mouth’ is changing dentistry

If you want your dental fillings, crowns, implants, and so on to last, you can thank ART.

Chewing involves some of the human body’s most complex motions, and ART, the artificial mouth at the University of Minnesota School of Dentistry, can perform a year’s worth of chewing—300,000 cycles—in just a day or two.

By reproducing the motions and forces at play in human chewing, ART is invaluable for testing the performance of dental materials and guiding their development. It chews with real teeth, teeth made of composite materials, or any other material an investigator wants to test, complete with a stream of water or artificial saliva.

First developed in 1983, ART—now in its fifth generation—has become the gold standard for testing dental materials without human volunteers.

“Our discoveries are in the technology used to evaluate materials,” says Ralph DeLong, professor and interim chair of the Department of Restorative Sciences, who built the original apparatus with an engineer from MTS Systems Corp. “ART-1 was the first artificial oral environment that chews effectively, using physiological parameters such as the force applied, where it’s applied, and what happens to teeth when you chew.”

ART-1 won the coveted IR-100 Award for 1983, placing it in the top 100 inventions of that year. Two of the many other notable robotic inventions by DeLong and his colleagues:

• DeLong and others developed a system to digitally map the 3-D profile of a tooth or a sample of dental material. A computer compares profiles before and after a chewing test to calculate the amount of wear. The number of chews that produce a given amount of wear indicates how well the test material will hold up in a real mouth.

• DeLong’s colleague Maria Pintado pioneered a toothbrushing machine. She outfitted toothbrushes to measure the motions and forces produced when many volunteers brushed, then programmed the machine to duplicate the various patterns and see what worked best. The results were used in toothbrush design.

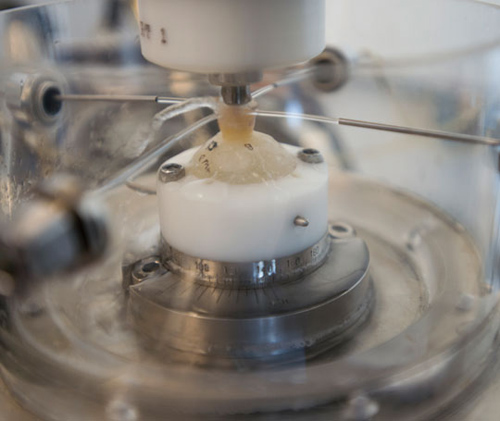

Closeup of the ART-1 artificial mouth, showing streams of lubricant trained on the point of contact between chewing surfaces. Image credit: University of Minnesota

Center of innovation

In 1991 professor William Douglas, along with scientists from 3M, created the first University-industrial center, dedicated to putting their technologies to work in dental product development.

Called the Minnesota Dental Research Center for Biomaterials and Biomechanics (MDRCBB), the center has just won another major prize: a William J. Gies Award for Vision, Innovation, and Achievement—the Oscar of dental education—given by the American Dental Education Association Gies Foundation. The center won in the category of “outstanding vision—public or private partner,” a tribute to its history of bringing farsighted research to fruition.

The center continues to evolve under Alex Fok, its director since 2007, who has added both technical capacity and industrial partners, including General Mills and orthodontics maker Ormco.

“The strength of the center is its ability to simulate oral challenges in the laboratory,” says Fok. This provides “a way for companies to identify and respond to challenges before they reach the time-consuming clinical trial phase.”

DeLong and colleagues are now designing the ART-5 machine, which will chew real food as realistically as possible—responding, for example, to texture.

“We don’t know how people chew food,” DeLong says. “We do know there are pressure sensors in periodontal tissue, and we speculate that it gives early information about how much [chewing] force is necessary.”

The goal is to improve dental implants, small metal cylinders used as anchors for a new tooth. Though tough, they lack the cushioning of periodontal tissue. DeLong and his colleagues will use ART-5 to determine the best occlusion, or meshing of teeth, to minimize stress on teeth with implants. They expect to have it up and running by December.

If it seems no test of dental materials or practices is beyond MDRCBB, you’re probably right.

“If you wanted to test dental floss, we’d figure it out,” DeLong says.

*Source: University of Minnesota