Applications range from protective coating to sterilize hospital surfaces and medical equipment or as an injection to more effectively treat patients

SAN JOSE, Calif. – 24 Jan 2013: Researchers from IBM and the Institute of Bioengineering and Nanotechnology revealed today an antimicrobial hydrogel that can break through diseased biofilms and completely eradicate drug-resistant bacteria upon contact. The synthetic hydrogel, which forms spontaneously when heated to body temperature, is the first-ever to be biodegradable, biocompatible and non-toxic, making it an ideal tool to combat serious health hazards facing hospital workers, visitors and patients.

Traditionally used for disinfecting various surfaces, antimicrobials can be found in traditional household items like alcohol and bleach. However, moving from countertops to treating drug resistant skin infections or infectious diseases in the body are proving to be more challenging as conventional antibiotics become less effective and many household surface disinfectants are not suitable for biological applications.

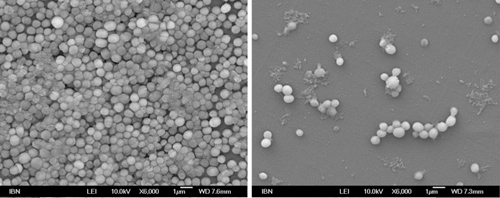

MRSA biofilm disrupted by hydrogel. On the left is a mature and healthy MRSA biofilm. After the hydrogel is applied, the biofilm is destroyed as seen on the right. The small portion of cells left have drastically disrupted membrane, preventing resistance. This type of biofilm disruption has not been reported in other antimicrobial hydrogels/synthetic polymers. Photo Credit: IBN

IBM Research and its collaborators developed a remoldable synthetic antimicrobial hydrogel, comprised of more than 90% water, which, if commercialized, is ideal for applications like creams or injectable therapeutics for wound healing, implant and catheter coatings, skin infections or even orifice barriers.

Able to colonize on almost any tissue or surface, microbial biofilms – which are adhesive groupings of diseased cells present in 80% of all infections – persist at various sites in the human body, especially in association with medical equipment and devices. They contribute significantly to hospital-acquired infections, which are among the top five leading causes of death in the United States and account for up to $11 billion in healthcare spending each year.

Despite advanced sterilization and aseptic techniques, infections associated with medical devices have not been eradicated. This is due, in part, to the development of drug-resistant bacteria. According to the CDC, antibiotic drug resistance in the U.S. costs an estimated $20 billion a year in healthcare costs as well as 8 million additional days spent in the hospital.

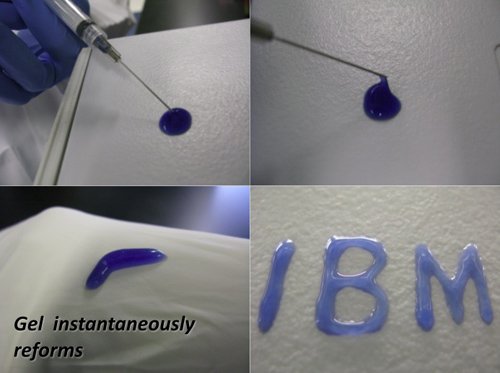

Polymer solution in gel form. The polymer solution, shown above in a remoldable gel form after heated to body temperature, is injectable for targeted treatment of bacterial infections and causes no adverse side effects. Photo Credit: IBN

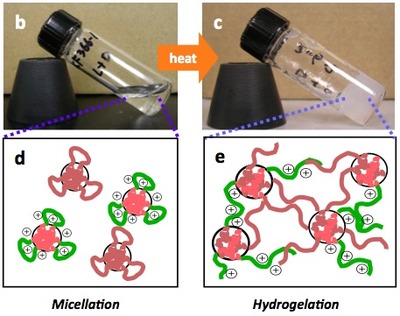

Through the precise tailoring of polymers, researchers designed macromolecules, a molecular structure containing a large number of atoms, which combine water solubility, positive charge, and biodegradability characteristics. When mixed with water and heated to body temperature the polymers self-assemble, swelling into a synthetic gel that is easy to manipulate. This highly desirable capability stems from self-associative interactions that create a “molecular zipper” effect. Analogous to how zipper teeth link together, the short segments on the new polymers also interlock, thickening the water-based solution into re-moldable and compliant hydrogels. Since they exhibit many of the characteristics of water-soluble polymers without being freely dissolved, such materials can remain in place under physiological conditions while still demonstrating antimicrobial activity.

“This is a fundamentally different approach to fighting drug-resistant biofilms. When compared to capabilities of modern-day antibiotics and hydrogels, this new technology carries immense potential,” said James Hedrick, Advanced Organic Materials Scientist, IBM Research, “This new technology is appearing at a crucial time as traditional chemical and biological techniques for dealing with drug-resistant bacteria and infectious diseases are increasingly problematic.”

When applied to contaminated surfaces, the hydrogel’s positive charge attracts all negatively charged microbial membranes, like powerful gravitation into a blackhole. However, unlike most antibiotics and hydrogels, which target the internal machinery of bacteria to prevent replication, this hydrogel kills bacteria by membrane disruption, precluding the emergence of any resistance.

“We were driven to develop a more effective therapy against superbugs due to the lethal threat of infection by these rapidly mutating microbes and the lack of novel antimicrobial drugs to fight them. Using the inexpensive and versatile polymer materials that we have developed jointly with IBM, we can now launch a nimble, multi-pronged attack on drug-resistant biofilms which would help to improve medical and health outcomes,” said Dr Yi-Yan Yang, Group Leader, Institute of Bioengineering and Nanotechnology, Singapore.

Polymer solution is ninety-percent water. The polymer solution is free flowing (b, d) at room temperature (71 degrees F). When heated to body temperature (98.6 degrees F), the polymers self-assemble into a cross-linked network, causing the solution to form a gel (c, e). Photo Credit: IBM

The IBM nanomedicine polymer program – which started in IBM’s Research labs only four years ago with the mission to improve human health – stems from decades of materials development traditionally used for semiconductor technologies. This advance will expand the scope of IBM and IBN’s collaborative program, allowing scientists to simultaneously pursue multiple methods for creating materials to improve medicine and drug discovery. An industry and institute collaboration of this scale brings together the minds and resources of several leading scientific institutions to address the complex challenges in making practical nanomedicine solutions a reality.

This research was recently published in the peer-reviewed journal, Angewandte Chemie.

For additional information, including high-resolution images and videos explaining the discovery, visit https://ibmhydrogels.tumblr.com/.

*Source: IBM