EAST LANSING, Mich. — Soybeans are one of the largest commodity crops in the world.

They also are starting to play a major role in reducing our carbon footprint, providing improved environmental performance and replacing finite, non-renewable resources such as oil.

And this is where Ramani Narayan comes in.

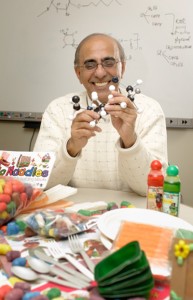

Ramani Narayan displays some of the products that are manufactured from materials derived from soybeans. A University Distinguished Professor of chemical engineering and materials science, Narayan has developed new methods of turning soybeans into bio-based products. Image credit: Michigan State University

The Michigan State University professor is taking the versatile legume and turning it into a variety of bio-based products, including paper coatings, adhesives, rigid and flexible urethane foams for insulation, and rubber products for use in tires and other automobile parts.

A University Distinguished Professor of chemical engineering and materials science, Narayan recently presented some details of his work at the annual meeting of the American Chemical Society in Philadelphia.

Working with a Michigan-based food processor – Zeeland Farm Services – Narayan and his team have developed ways of using all of the soybean, including the meal, oil and hull, in new and profitable ways.

“We’ve developed a technology to convert the soybean oil into materials that can be used for plastic products, urethane foams used in insulation and in the automotive and furniture industries, and materials for use in the cosmetic and nutritional supplements industries,” Narayan said.

The soybean meal can be converted through a series of chemical transformations into polyurethanes that are used for various auto parts, sealants and other products.

Narayan said an isocyanate-free process is used to develop the materials. Isocyanates are the key reactants in the manufacture of polyurethanes, but are highly toxic.

“We are substituting fossil-based products with biobased products,” Narayan said, “thus reducing carbon footprint, improving end-of-life environmental performance and contributing to improving the bio-manufacturing economy of the state.”

Narayan works closely with Zeeland Farm Services, a family-owned business that processes about 25,000 bushels of soybeans per day grown by 2,500 Michigan farmers. It is the largest soybean processer in the state.

“Working with Zeeland,” Narayan said, “helps create value-added industrial products. If we can take the oil, husk and meal of the soybean and convert it into new industrial products, we’re helping support the farmers who grow the crops and create new products and biomanufacturing jobs, thereby contributing to the overall economy of the state of Michigan.”

For information on Zeeland Farm Services, visit www.zfsinc.com.

*Source: Michigan State University